ZONESUN ZS-AFMW Automatic Bottled Water Washing Filling Capping 3-in-1 – Zonesunmall

Introduction:

The water bottling industry plays a vital role in providing safe and convenient drinking water to consumers worldwide. Behind the scenes, water bottling lines are the backbone of this industry, ensuring efficient and reliable production processes. In this article, we delve into the world of water bottling lines, exploring their significance, components, and the latest trends shaping the industry.

The Significance of Water Bottling Lines:

Water bottling lines are a series of interconnected machines and equipment designed to automate the process of filling, capping, labeling, and packaging bottled water. These lines enable high-volume production, ensuring consistent quality, hygiene, and productivity. With the global demand for bottled water on the rise, efficient water bottling lines are crucial for meeting consumer needs and industry standards.

Key Components of a Water Bottling Line:

-

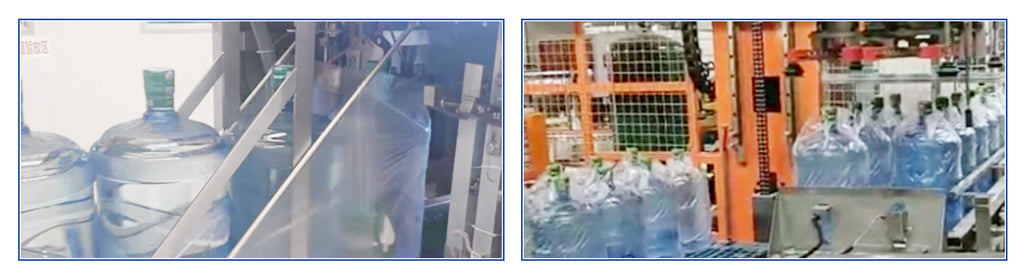

Bottle Washing: The first step in the water bottling process involves thoroughly cleaning and rinsing bottles to remove any contaminants or impurities. Automated bottle washing machines use a combination of water, sanitizing agents, and brushes to ensure proper hygiene.

-

Filling: Once clean, the bottles move on to the filling stage, where automated filling machines accurately measure and dispense the desired amount of water into each bottle. These machines utilize advanced technologies such as gravity filling, pressure filling, or volumetric filling to achieve precise and consistent fill levels.

-

Capping: After filling, the bottles proceed to the capping station, where specialized capping machines securely seal the bottles with caps or closures. Various capping methods, including screw caps, snap caps, or tamper-evident caps, ensure the integrity and freshness of the bottled water.

-

Labeling and Packaging: In the final stages, labeling machines affix labels with product information, branding, and regulatory details to the bottles. Once labeled, the bottles are then efficiently packaged using automated systems such as shrink-wrapping machines or case packers, ready for distribution and retail.

Latest Trends in Water Bottling Lines:

-

Sustainability and Eco-Friendly Practices: With growing environmental concerns, water bottling lines are embracing sustainable practices. This includes using eco-friendly packaging materials, optimizing energy consumption, and implementing water-saving technologies during the bottling process.

-

Advanced Automation and Integration: Automation and integration are key trends in the water bottling industry. Cutting-edge technology, such as robotics and artificial intelligence, is being integrated into bottling lines to enhance efficiency, minimize downtime, and improve overall productivity.

-

Quality Control and Traceability: Stringent quality control measures and traceability systems are becoming increasingly important in water bottling lines. Advanced sensors, cameras, and software solutions are employed to monitor and track each bottle throughout the production process, ensuring product safety and compliance.

-

Customization and Personalization: Consumer preferences for personalized products are driving the demand for customizable water bottles. Water bottling lines are adapting to accommodate various bottle sizes, shapes, and labeling options, allowing for unique branding and product differentiation.

Conclusion:

Water bottling lines are fundamental to the success of the water bottling industry. By incorporating advanced technologies, sustainable practices, and a focus on quality control, these lines enable efficient production, packaging, and distribution of bottled water. As the industry continues to evolve, embracing automation, customization, and eco-conscious practices, water bottling lines will play a pivotal role in meeting consumer demands for safe, refreshing, and environmentally responsible bottled water.